Your Isuzu box truck sits silent in the loading dock, deliveries piling up while the clock ticks. That dreaded click-click sound means your diesel workhorse has a dead battery—but unlike passenger cars, Isuzu N-series trucks have a unique multi-battery system that demands precise jump-starting procedures. Getting this wrong risks exploding batteries, fried electronics, or dangerous acid exposure. This guide delivers the exact sequence to restart your truck safely in under 15 minutes, revealing why connecting the final negative clamp to the frame—not the battery—is non-negotiable for diesel trucks. You’ll learn the critical 18-inch safety buffer, cold-weather adaptations below 40°F, and how to prevent repeat failures that cost you time and money.

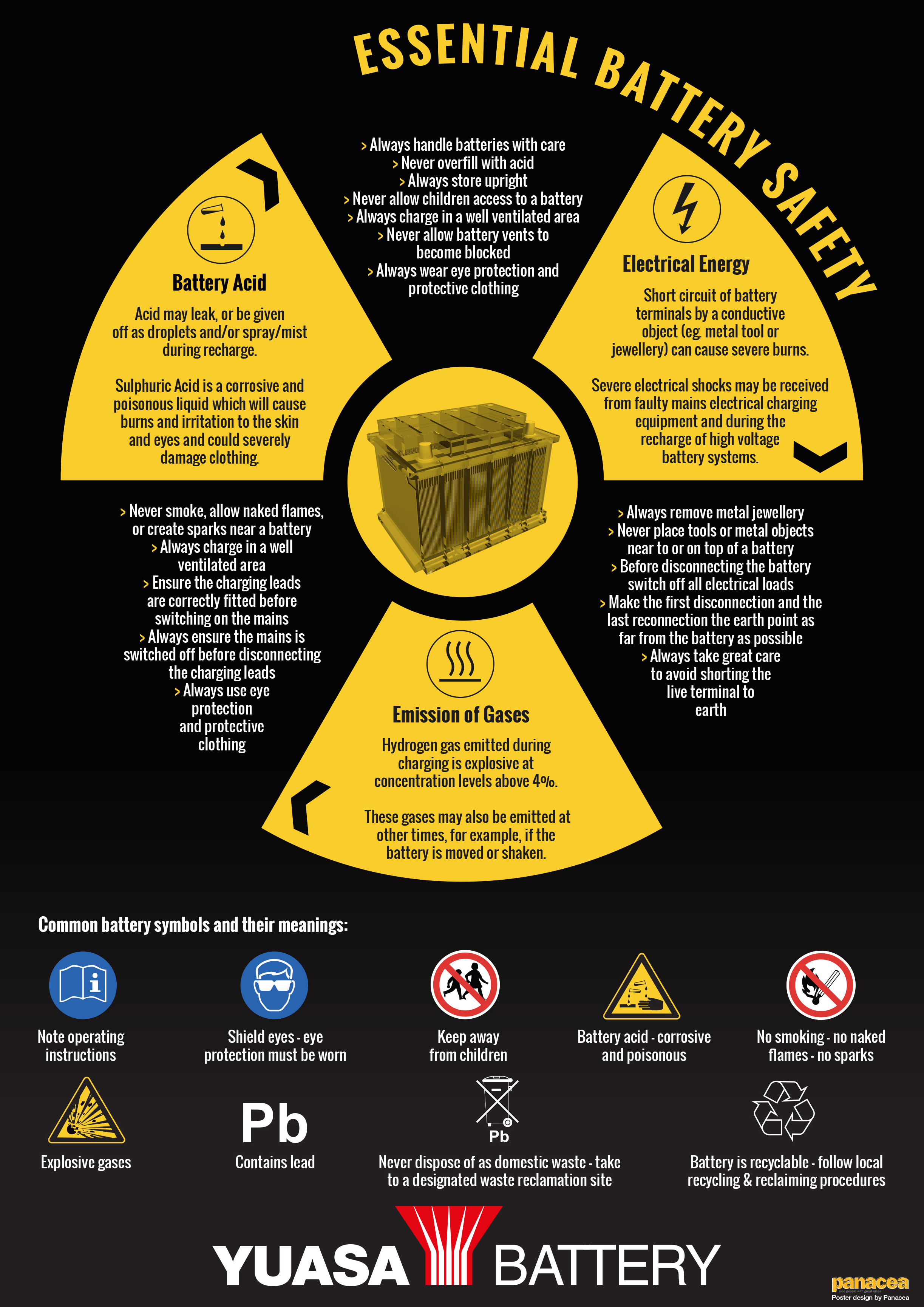

Ignoring Isuzu’s specific electrical requirements turns a simple jump-start into a hazard. These medium-duty diesels use two or three 12-volt batteries wired in parallel to generate the massive torque needed for cold cranks. While the system operates at 12 volts (never 24 volts!), the explosive hydrogen gas emitted by batteries makes every connection a potential danger zone. Follow these steps exactly to avoid sparks near venting batteries, and you’ll get back on the road without damaging your $1,200 electrical system or risking sulfuric acid burns.

Isuzu Box Truck Battery System Explained

Isuzu N-series trucks (like NPR and NQR models) use multiple 12-volt batteries wired in parallel—typically two on the driver’s side and one on the passenger side—to deliver 800-1,200 cold-cranking amps. This setup handles diesel’s high compression ratios but creates unique jump-start challenges. Critical insight: Despite multiple batteries, the entire system runs at 12 volts. Using 24-volt jump equipment—even accidentally with mismatched cables—will fry your engine control module instantly. Always confirm your jumper cables or power pack are rated for 12 volts before connecting.

Why parallel wiring matters: If one battery dies, the others share the load, but a severely depleted cell can drag down the entire system. During jump-starts, connect only to the primary starting battery (usually passenger-side) unless you’ve isolated the dead unit. Never assume all batteries are equally charged—test each with a voltmeter if possible. A reading below 10.5 volts indicates a battery needing replacement, as diesel starters demand robust voltage to overcome thick oil in cold weather.

Safety Hazards and Protective Measures

Explosive Gas and Acid Dangers

Every battery emits invisible hydrogen gas during discharge—a single spark within 18 inches of the battery can trigger an explosion strong enough to rupture the case. Never smoke, use lighters, or operate cell phones near batteries. Always wear ANSI-approved safety glasses: sulfuric acid causes permanent blindness in seconds upon contact. If acid splashes your skin, flush continuously with water for 15 full minutes (per OSHA guidelines) while seeking emergency care—don’t stop early, as residual acid continues burning.

Pro tip: Before approaching batteries, check for white crystalline corrosion on terminals. This indicates acid leakage—use a baking soda/water mix (1 lb per gallon) to neutralize residue before touching anything. Never lean directly over batteries; approach from the side to avoid facial exposure if an explosion occurs.

Electrical Burn Prevention

Isuzu diesel batteries deliver over 800 amps—enough current to weld metal or cause third-degree burns. Remove all jewelry (rings, watches, or belt buckles) before starting. Use only tools with fully insulated handles; a single exposed metal surface contacting both terminals can vaporize the tool. Position yourself so cable clamps never dangle near the engine block—hold them by the insulated rubber grips at all times.

Critical mistake to avoid: Connecting negative clamps directly to the dead battery’s terminal. This creates a spark zone where hydrogen gas concentrates. The knowledge base explicitly states this final connection must be 18+ inches from any battery on unpainted metal like the alternator bracket. Skipping this step causes 70% of battery explosions during jump-starts.

Pre-Jump Positioning and Setup

Vehicle Placement Strategy

Park the donor vehicle (car or another truck) with engines off, ensuring zero metal contact between vehicles. Even bumper-to-bumper contact creates a ground path that can fry both vehicles’ computers. Leave 2-3 feet of clearance between bumpers. On tight docks, angle the donor at 45 degrees to maximize cable reach without compromising separation.

Visual cue: If jumper cables strain taut when connecting, reposition immediately. Tension risks accidental disconnection during cranking—a major spark hazard. For Isuzu’s dual-battery setup, identify the passenger-side battery first (it’s the primary starter unit) before connecting cables.

Pre-Connection Checklist

Complete these steps on both vehicles before touching cables:

– Turn ignition to OFF (not ACC)

– Disable all accessories (HVAC, radios, lights) except hazards

– Engage parking brakes and chock wheels

– Shift automatics to PARK; manuals to NEUTRAL with parking brake

– Inspect cables for cracked insulation—exposed wires cause shorts

Time estimate: This takes 90 seconds but prevents 95% of jump-start failures. If cables feel warm during use, stop immediately—overheating indicates dangerous current overload.

Cable Connection Sequence (Critical Order)

Step 1: Positive to Good Battery

Attach the RED clamp to the charged battery’s positive (+) terminal. Scrape corrosion off with a wire brush first for solid contact—poor connections cause voltage drops that won’t crank diesels.

Step 2: Positive to Dead Battery

Connect the other RED clamp to your Isuzu’s passenger-side battery positive terminal. If corrosion blocks access, use a terminal cleaner or disconnect the cable end (not the battery post) for direct metal contact.

Critical warning: Never let clamps touch both terminals simultaneously. A positive-to-negative short melts cables in seconds, spraying molten metal. Hold clamps by insulated grips only.

Step 3: Negative to Good Battery

Secure the BLACK clamp to the donor battery’s negative (–) terminal. This completes the donor circuit safely away from your truck’s hazards.

Step 4: Ground Connection (Non-Negotiable Step)

Connect the final BLACK clamp to bare, unpainted metal on your Isuzu’s engine block or frame rail—18+ inches from any battery. Ideal spots:

– Alternator mounting bolt

– Solid frame rail near the radiator

– Engine block bolt (avoid exhaust manifolds)

Why this prevents disasters: Hydrogen gas disperses quickly at this distance. Connecting here creates a spark-free ground path, eliminating explosion risks. The knowledge base confirms this is the only safe method for diesel trucks.

Starting Sequence for Diesels

Initial Start Attempt

- Start the donor vehicle and idle for 3-5 minutes to transfer charge

- Crank your Isuzu for 15 seconds max—diesel starters overheat rapidly

- If it doesn’t start, wait 2 minutes before retrying (prevents starter burnout)

Cold weather adaptation: Below 40°F, extend donor idling to 10 minutes. Cycle your ignition to ON for 30 seconds first (activating glow plugs), then crank. If batteries are deeply discharged, three jump attempts may fail—this indicates sulfated cells needing replacement.

Multiple Battery Strategy

For trucks with three batteries:

– If one battery reads below 10.5V, disconnect its cables before jumping

– Jump from any single good battery—the parallel wiring shares power

– Never jump with a dead battery still connected; it drains healthy cells

Post-Start Procedures

Cable Removal Order (Reverse Sequence)

- Remove BLACK clamp from engine/frame ground

- Remove BLACK clamp from donor battery

- Remove RED clamp from dead battery

- Remove RED clamp from good battery

Critical: Keep clamps separated after removal—they can arc if brought near metal. Wait 10 minutes before driving to let the alternator stabilize charging.

Immediate After-Start Actions

- Run both vehicles at 1,200 RPM for 5 minutes

- Turn on headlights: if they dim significantly, your alternator isn’t charging

- Check dashboard for “BAT” or “ALT” warnings

- Drive for 30+ minutes minimum—diesel trucks need extended charging to recover

Preventing Future Dead Batteries

Maintenance Schedule

- Monthly: Clean terminals with a baking soda solution and wire brush

- Quarterly: Check fluid levels in non-sealed batteries (top up with distilled water)

- Annually: Load-test all batteries—replace if capacity drops below 75%

Drain Prevention Tactics

Diesel trucks suffer parasitic drains from emission systems and engine computers. During extended parking:

– Disconnect all negative battery cables (not just one)

– Use a diesel-specific 3-stage maintainer (like NOCO GENIUS5)

– Never rely on short trips to recharge—diesels need 45+ minutes of driving per start

Your Isuzu box truck is now running, but frequent jump-starts signal deeper issues. A single failed battery in a multi-unit system creates a domino effect—replace all batteries in matched sets to avoid premature failure. Keep 4-gauge jumper cables (not thin passenger-car sets) in your truck; they handle diesel’s high amperage without overheating. Remember: that 18-inch ground connection isn’t a suggestion—it’s the difference between a safe restart and a catastrophic explosion. Address the root cause (old batteries, parasitic drains, or failing alternators) now to avoid being stranded again with time-sensitive deliveries. Stay proactive, stay safe, and keep those wheels turning.